Sustainable packaging: Dolphin Pack's commitment to greener packaging

Cutting-edge packaging solutions for a greener future and reduced environmental impact

The packaging industry is often the subject of debate due to its widespread use of plastics and non-recyclable materials, which contribute to waste accumulation and environmental impact. Growing environmental awareness among consumers and businesses has made reducing environmental impact a global priority. In light of this, taking concrete measures has become a priority.

Aware of this need, Dolphin Pack has been working for years to make its production and packaging machines more sustainable. Our common goals include limiting CO₂ emissions, reducing fossil fuel consumption, choosing more sustainable packaging materials, and producing responsibly. Our company wants to actively participate in this vision by offering concrete solutions for a greener future.

How can packaging be made more sustainable?

At Dolphin Pack, making packaging more sustainable has become a primary goal. Thanks to our ongoing commitment to research and innovation, we have achieved significant progress, particularly since 2022.

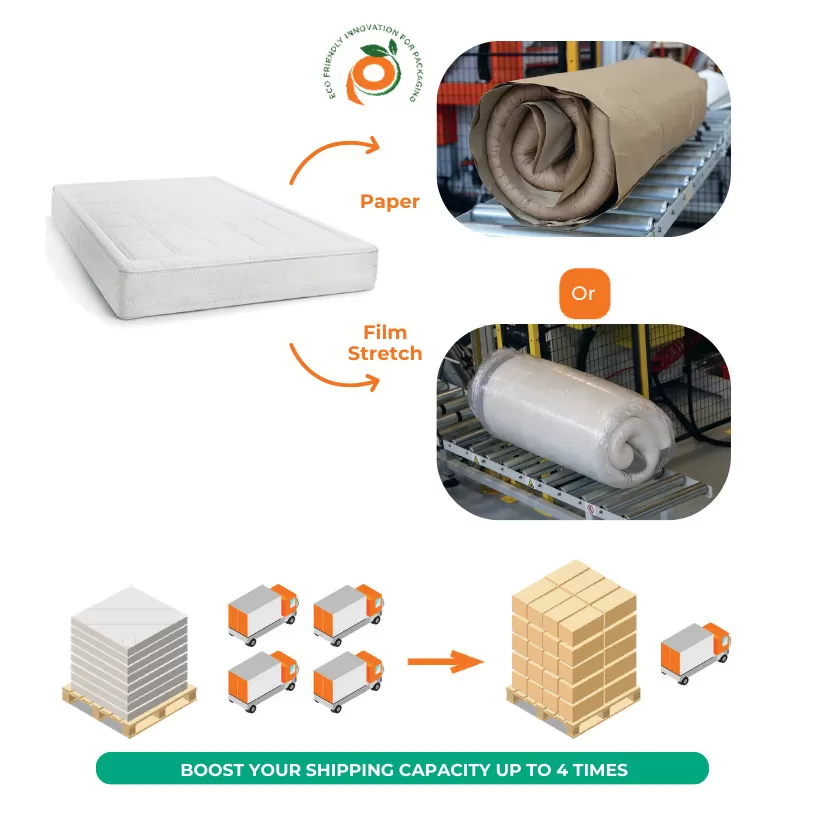

In fact, it was in that year that we introduced the option of using paper for packaging in our automatic mattress packaging line, a material with a significantly lower environmental impact than traditional polyethylene (PE).

Our team of engineers worked hard to ensure this model of packaging machine could handle paper efficiently without compromising performance or reliability.

For the initial packaging stage, i.e. compressing the mattress, we use polythene paper consisting of 95% paper and a thin 5% layer of polyethylene. This combination enables sealing with our standard sealing bars without the need for structural modifications.

During the rolling phase, however, we use 100 per cent paper, which is sealed using hot-melt glue applied with a gun, rather than welding. This in-house developed system allows for a clean, waste-free process with a reliable, long-lasting seal.

Thus, the Etesian Smart Hybrid line was born: a solution that packages, compresses, folds and rolls mattresses using both plastic and paper. Where possible, we also develop customised solutions to incorporate paper packaging into customers' existing mattress production lines, enabling them to upgrade to more environmentally friendly solutions.

We have also extended the use of paper as a packaging material to polyurethane blocks. With this in mind, we created the Burian Green, a machine designed to compress and roll up blocks up to four metres long.

The Burian Green is distinguished by its ability to compress the product and proceed directly to rolling without an initial flat packing process. Paper is only used as packaging material at the rolling stage, which is then sealed with hot glue to ensure an efficient, sustainable process with a long-lasting seal.

Energy efficiency: an integrated commitment in Dolphin Pack machines

In addition to innovative materials, state-of-the-art systems optimise energy consumption, enhancing the sustainability of our packaging machines. The patented cold sealing bar system, for example, significantly reduces the need for continuous heating, thus decreasing energy consumption. Servo pumps on some lines ensure that energy consumption is proportional to the actual workload, thereby avoiding unnecessary waste. Finally, the Start & Stop mode ensures that machines only activate when necessary, minimising energy absorption during breaks and maximising overall efficiency.

Innovations in packaging to reduce CO2 emissions

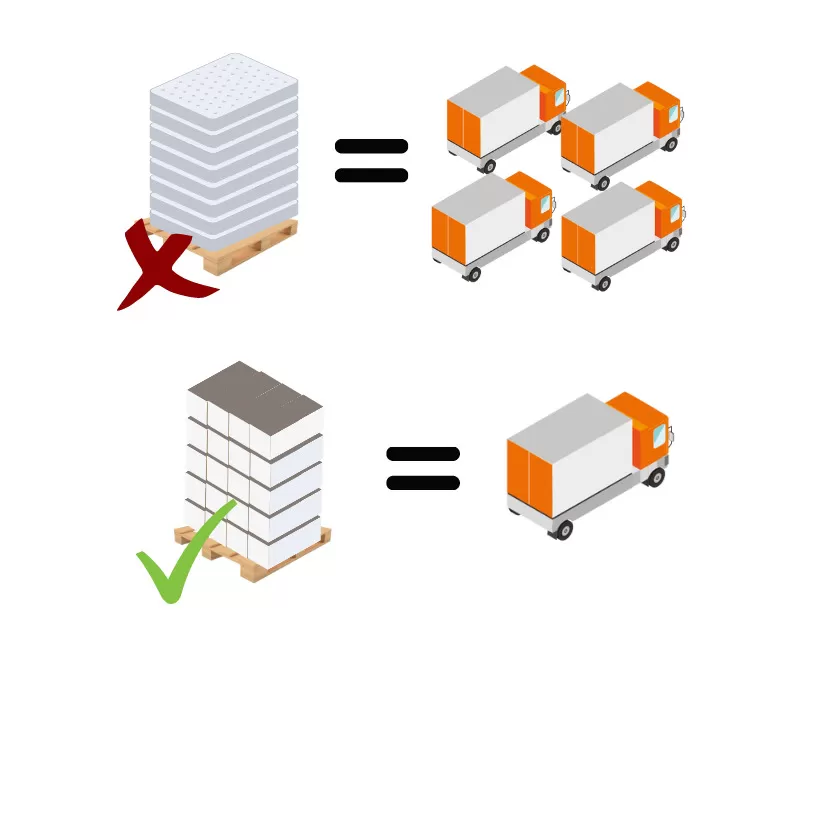

Another key area on which Dolphin Pack has focused its efforts is reducing the volume of products transported. Years of study and the development of innovative machines capable of compressing products without damaging them have made this possible. State-of-the-art machines such as the Levante BL and the Burian for polyurethane blocks, as well as the aforementioned Etesian Smart Hybrid for mattresses, allow compressible products to be packed by significantly reducing their volume — by up to 80% in some cases.

This optimisation means fewer trips are needed to transport the products, resulting in a substantial reduction in CO₂ emissions produced during logistics. For example, compression enables a much higher number of items to be loaded per shipment — for instance, an increase from 12 to 40–42 blocks per truck. This increased efficiency leads to economic savings of 70–75% and a reduction of over 2 tonnes of CO₂ emissions per 1,000 km of transport, as detailed in our news article on solutions to reduce costs and environmental impact in polyurethane packaging. Dolphin Pack's commitment to making packaging more efficient protects the environment and offers companies a direct economic benefit.

The energy of the future: Dolphin Pack's commitment to renewable energy sources

The company's dedication to sustainability extends beyond the innovation of machinery and materials. The company recognises that a real transformation towards a greener future also involves reducing dependence on fossil fuels in its operations. To this end, we have taken a significant step by installing photovoltaic panels on the roof of our factory. This strategic decision enables us to generate a substantial portion of the energy required for our operations directly from renewable sources, thereby reducing the carbon emissions linked to energy consumption and reinforcing our position as a leading company in sustainable packaging.

At Dolphin Pack, we will continue to invest in research and development to make our machinery and processes even more sustainable, setting the course for an increasingly green future. If you want your company to make a difference with truly sustainable packaging, contact us to discover our innovative solutions.